On Friday, September 27 I attended a workshop at UVic’s Digital Scholarship Commons on 3D Printing. I have never done this before, but am aware that it is an ever-growing domain in manufacturing and design. I took it mainly to become more well-versed in how the technology works, how it may be integrated in my future science lessons and to expand my imagination for what is capable with this tool.

Fused deposition modelling schematic.

Briefly, we learned about Fused Deposition Modelling in which minute layers of plastic are extruded and sliced to construct objects in 3D. The primary material is polylactic acid, a thermoplastic aliphatic polyester which is derived from renewable biomass (corn, sugar beet, etc.). This plastic is quite non-elastic and is prone to shatter and is therefore often reinforced during the printing process and with internal scaffolding called ‘infill’.

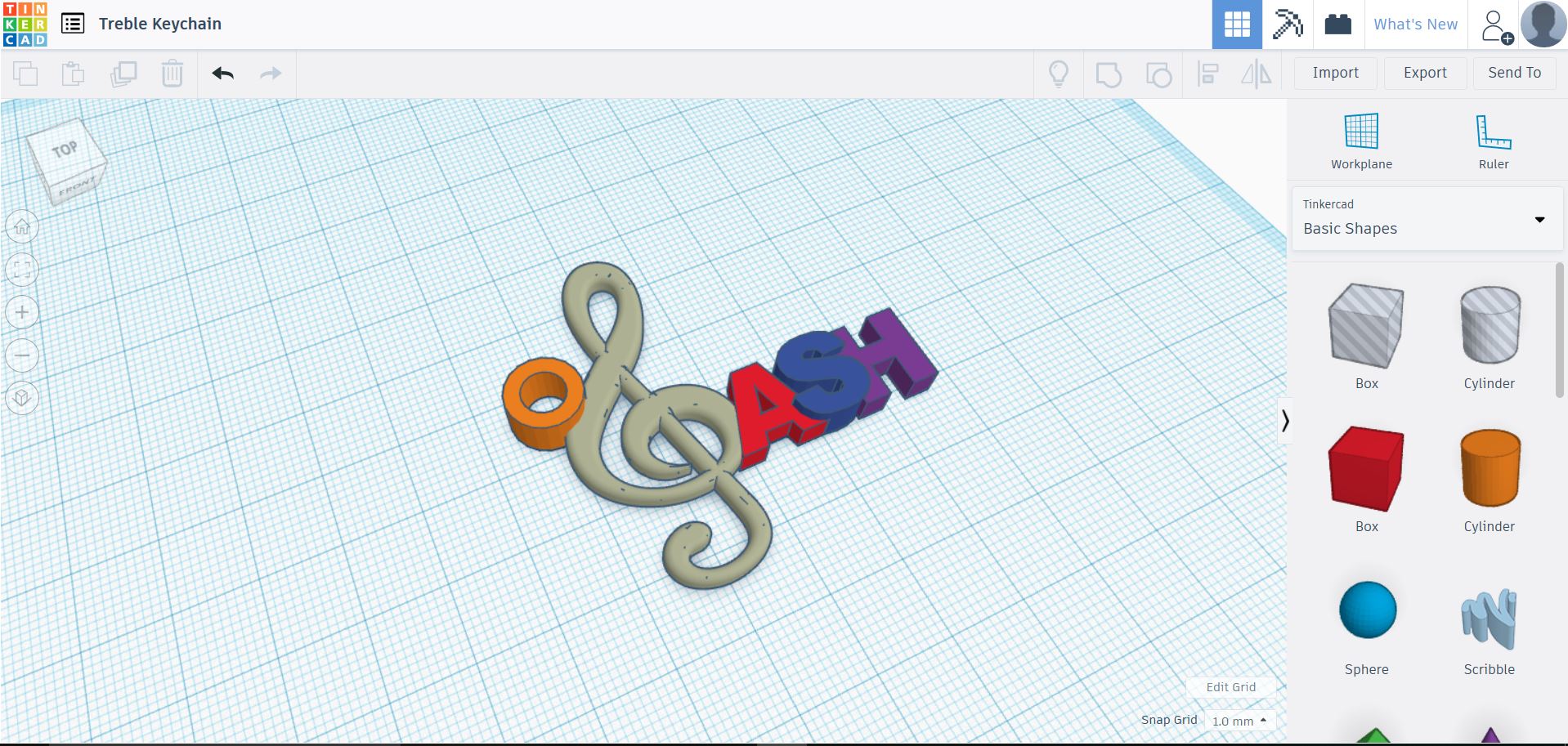

In the workshop, I designed two items. A 6-sided die and a keychain. The main platform we used was called TinkerCAD, a browser based computer-aided design program that allows you to easily construct objects and export them in a printable format. Having done some drafting in high school (thanks Mr. Hansen), I found the software to be very intuitive and easy to work with. In addition to this platform, we also accessed free 3D plans from Thingiverse, an online community for sharing schematics with others. The treble clef used in my keychain design posted below was taken from Thingiverse & modified with TinkerCAD.

My 3D Design in TinkerCAD

The final product

The workshop was fun, interesting and definitely got the wheels turning for potential applications in the classroom and at home. To give us a sense of scope, the workshop leader, Dani, told us about some incredible projects that involved using 3D printing including a group which developed a hyper-affordable, $200 3D-printed prosthetic hand for use in developing countries.

Finally, it did not go unnoticed to me that the workshop occurred on the same day as the Global Climate March. I felt a little bit conflicted attending it and felt compelled to investigate the environmental impacts of 3D printing. An article by Megan Nichols weighs the costs and benefits of 3D printing. According to her analysis, 3D printing consume 50-100 times more electricity than equivalent production methods. However, this impact can be offset by the notable benefits of using less material, producing items locally (thus reducing distribution emissions) and using recyclable thermoplastics in the future. I personally see the potential for 3D printing to reduce our environmental impact when used strategically to provide small-batch items when needed and limit unnecessary manufacture.

For any others interested in taking this 3D printing workshop, there are two other dates this fall (October 10th & 28th) and registration is available.

-S

Michael Paskevicicius

Excellent, thanks for sharing your experience at the workshop!

Milan

I made this at the Toronto Reference Library: Bathsheba’s Antichron.

You can get the file online.

Milan

The Economist also had some articles about additive manufacturing.